In today’s industrial landscape, precision and accuracy are paramount, and the tools used to achieve these standards are equally critical. One such essential tool is the display instrument, a device that plays a pivotal role in monitoring, controlling, and displaying various parameters in industrial processes. As a leader in the instrumentation industry, “Pabrik Instrumen Hongguang” is dedicated to providing high-quality display instruments that meet the rigorous demands of modern industries. This guide will explore what display instruments are, their key features, applications, and why they are indispensable in industrial settings.

Understanding Display Instruments

A display instrument is an electronic device designed to measure, monitor, and visually display critical parameters such as temperature, pressure, flow rate, voltage, and other process variables. These instruments are integral to ensuring that industrial processes operate within the desired parameters, thereby maintaining efficiency, safety, and product quality.

Key Components of Display Instruments

- Sensor or Transducer

- Definition: The sensor is the component that detects and measures the physical quantity (e.g., temperature, pressure) and converts it into an electrical signal. In some cases, a transducer may also be used to convert the signal into a readable format for the display.

- Importance: The accuracy of the sensor directly affects the overall precision of the display instrument. High-quality sensors, like those used in Hongguang Instrument Factory’s products, ensure reliable and accurate measurements.

- Signal Processor

- Definition: The signal processor interprets the electrical signals received from the sensor and prepares them for display. This involves filtering, amplifying, and converting the signals to ensure they are accurate and meaningful.

- Importance: The signal processor is crucial for minimizing noise and ensuring that the data presented on the display is both accurate and easy to interpret.

- Display Interface

- Definition: The display interface is the component that visually presents the measured data to the user. It can be an analog gauge, a digital readout, or a more advanced graphical interface.

- Importance: A clear and intuitive display interface, like those designed by Hongguang Instrument Factory, is essential for quick and accurate data interpretation by operators.

- Catu Daya

- Definition: The power supply provides the necessary energy for the display instrument to operate. Depending on the design, this could be a battery, a connection to the mains, or an external power source.

- Importance: Reliable power ensures continuous operation and accurate measurements, especially in critical applications.

Types of Display Instruments

Display instruments come in various forms, each tailored to specific industrial applications. Some common types include:

- Digital Panel Meters

- Overview: Digital panel meters display numerical data, typically in a digital format. They are commonly used for monitoring voltage, current, and other electrical parameters in industrial control panels.

- Specifics: Hongguang Instrument Factory’s digital panel meters offer high-resolution displays with up to 0.01% accuracy, making them ideal for precision monitoring.

- Analog Gauges

- Overview: Analog gauges provide a visual representation of measurements via a needle or dial. They are often used in applications where a quick visual check is needed, such as monitoring pressure in HVAC systems.

- Specifics: Our analog gauges feature robust construction and high visibility, with a measurement range of up to 1000 psi for pressure gauges.

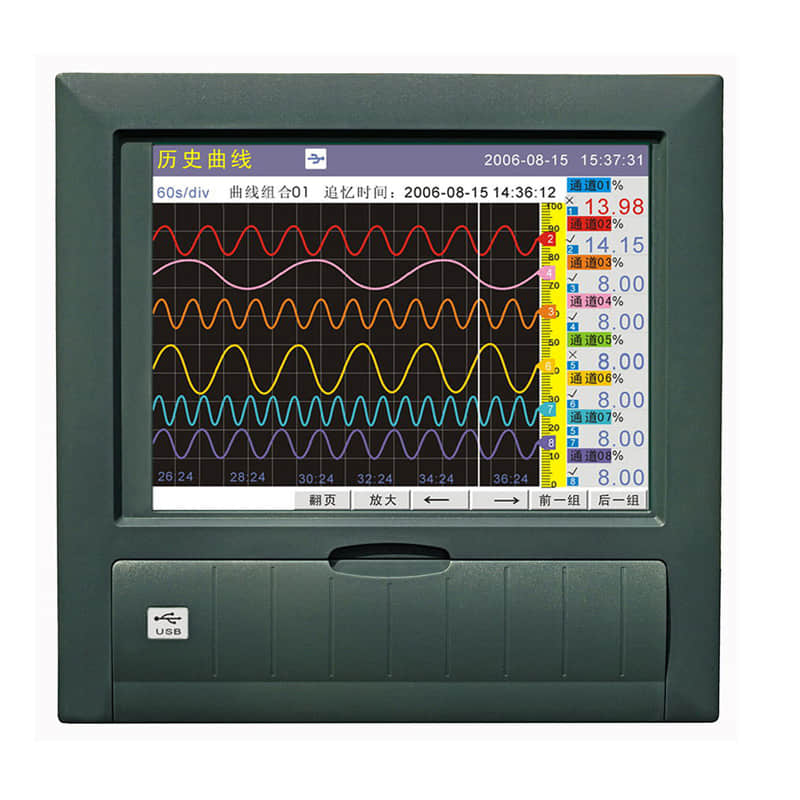

- Graphical Display Instruments

- Overview: Graphical displays offer more advanced visualization options, such as trend graphs, bar charts, and real-time data logging. These instruments are ideal for complex processes that require continuous monitoring.

- Specifics: The graphical display instruments from Hongguang Instrument Factory support multi-channel inputs and can display up to four parameters simultaneously on a 7-inch color screen.

Applications of Display Instruments

Display instruments are used across a wide range of industries, each with specific needs and challenges. Some common applications include:

- Manufacturing

- Penggunaan: Display instruments monitor critical parameters such as temperature, pressure, and flow rate in manufacturing processes. This ensures that products are made to specification and that the processes are efficient.

- Trade Data: According to recent market reports, the global industrial display market was valued at approximately USD 4.1 billion in 2022, with a projected growth rate of 7.2% CAGR from 2023 to 2028. This growth is driven by the increasing demand for automation and precision in manufacturing.

- Energy and Utilities

- Penggunaan: In the energy sector, display instruments monitor power generation and distribution parameters, ensuring system stability and efficiency. They are critical in applications such as monitoring the output of solar panels or the pressure in natural gas pipelines.

- Specifics: Hongguang Instrument Factory’s display instruments are used in over 500 energy facilities worldwide, ensuring reliable and accurate monitoring of critical parameters.

- Healthcare

- Penggunaan: In medical settings, display instruments are used to monitor vital signs and other critical parameters in patient care. For example, they are found in devices like blood pressure monitors and infusion pumps.

- Specifics: Our instruments meet stringent medical standards, offering accuracy within ±0.5% for critical healthcare applications.

- Environmental Monitoring

- Penggunaan: Display instruments are essential in monitoring environmental conditions, such as air and water quality, ensuring compliance with safety and environmental regulations.

- Trade Data: The environmental monitoring equipment market is expected to grow by 6.5% annually, reflecting the increasing need for accurate data in environmental protection efforts. Hongguang Instrument Factory is committed to providing reliable instruments that support these initiatives.

Best Practices for Using Display Instruments

To ensure the longevity and accuracy of display instruments, it’s important to follow certain best practices:

- Regular Calibration

- Importance: Regular calibration ensures that the instrument continues to provide accurate measurements over time. Calibration should be done according to the manufacturer’s recommendations, typically annually or biannually.

- Proper Installation

- Importance: Ensuring that the instrument is installed in the correct location and orientation is critical for accurate measurements. For instance, temperature sensors should be placed away from direct heat sources that could skew readings.

- Routine Maintenance

- Importance: Routine checks for wear and tear, along with cleaning the display and sensors, help maintain the instrument’s performance. Hongguang Instrument Factory offers comprehensive maintenance support to ensure your instruments remain in top condition.

Kesimpulan

Display instruments are indispensable in today’s industrial landscape, providing the accuracy and reliability needed to monitor and control critical processes. Whether you’re in manufacturing, energy, healthcare, or environmental monitoring, choosing the right display instrument is crucial for maintaining efficiency and safety. At Hongguang Instrument Factory, we pride ourselves on delivering high-quality display instruments that meet the diverse needs of our clients. With advanced features, robust construction, and a commitment to accuracy, our instruments are designed to support the most demanding industrial applications. As the global market for display instruments continues to grow, Hongguang Instrument Factory remains at the forefront, offering innovative solutions that drive excellence in industrial monitoring and control.

Product: Perekam Tanpa Kertas PR5100