In fluid systems, precise measurement and monitoring of both flow and pressure are essential for ensuring optimal operation, efficiency, and safety. Whether it’s in industrial, chemical, water treatment, or HVAC systems, having the right instruments for monitoring these parameters is crucial for maintaining performance and preventing costly breakdowns.

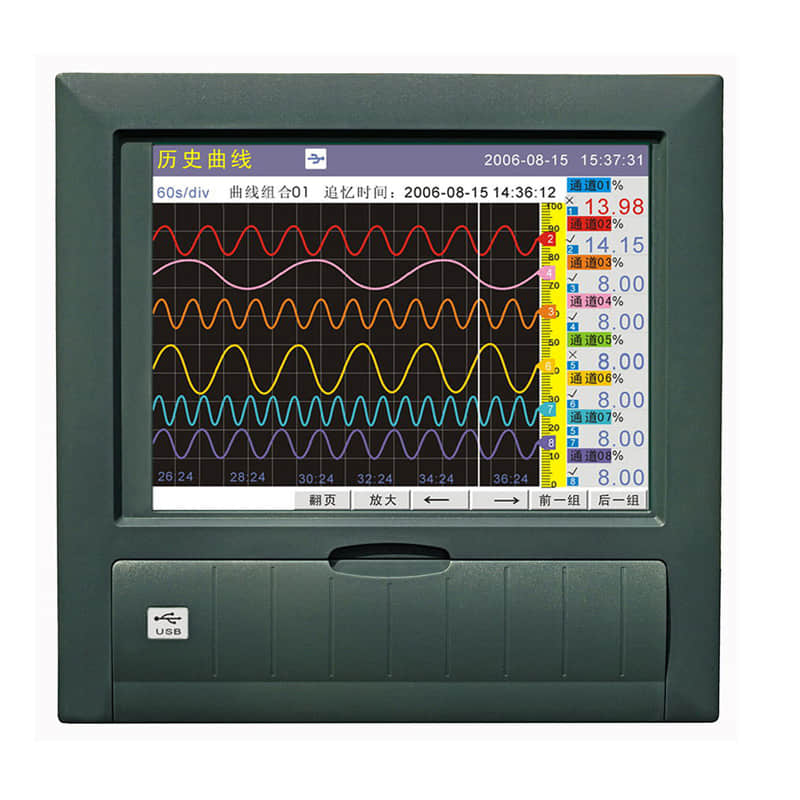

Display instruments, such as flow meters and pressure gauges, are widely used to visually indicate real-time measurements of fluid flow and pressure. These instruments provide operators with valuable data, enabling them to make informed decisions, automate controls, and take corrective actions when needed. In this article, we will explore the different types of display instruments used for flow and pressure monitoring, how to use them effectively, and provide a comparison of peer products to help you choose the best solution for your system.

Importance of Monitoring Flow and Pressure in Fluid Systems

1. Flow Monitoring

Flow monitoring is critical in fluid systems, as it ensures that the right amount of fluid is moving through the system at the correct velocity. Accurate flow measurement helps with:

- Optimizing process efficiency: Maintaining consistent flow rates is key for energy efficiency and proper system operation.

- Preventing damage: Monitoring flow ensures that equipment like pumps, valves, and pipes are not subjected to conditions that could cause wear or failure.

- Flow balancing: Ensures that the system remains balanced, whether it is distributing fluids across different parts of a plant or controlling fluid consumption.

2. Pressure Monitoring

Pressure monitoring ensures that fluid systems remain within operational limits. High or low pressure can lead to:

- System failures: Exceeding pressure limits can cause pipes to burst, valves to fail, or pumps to overload.

- Energy waste: Improper pressure can lead to inefficiencies in system performance, requiring more energy to maintain desired flow rates.

- Process control: For many processes, maintaining a consistent pressure is critical for the quality of the output, such as in chemical reactions, filtration, or fluid mixing.

Benefits of Display Instruments

- Real-time monitoring: Operators can quickly check system parameters to ensure that both flow and pressure remain within safe ranges.

- Automation and control: Display instruments can be integrated with control systems to automatically adjust valves, pumps, or compressors based on real-time readings.

- Preventative maintenance: Continuous monitoring allows for early detection of potential issues, enabling preventative actions before costly damage occurs.

Types of Display Instruments for Monitoring Flow and Pressure

1. Flow Meters

Flow meters are used to measure the amount of fluid passing through a pipe or system over a given time period. They are essential for monitoring the flow rate, ensuring that fluids are moving at the right speed and in the right volume.

There are several types of flow meters, each designed for specific applications:

- Electromagnetic Flow Meters: Ideal for conductive liquids, electromagnetic flow meters measure the velocity of the fluid as it passes through a magnetic field. These meters are widely used in wastewater treatment, chemical plants, and food & beverage industries.

- Turbine Flow Meters: These meters use a turbine that spins as fluid flows through it. The speed of the turbine is proportional to the flow rate. Turbine flow meters are often used in oil and gas pipelines and petrochemical plants.

- Ultrasonic Flow Meters: These meters use the time-of-flight principle to measure flow rate. They are ideal for non-invasive flow measurements in large pipes and are used in water distribution, HVAC systems, and large-scale fluid transport.

- Coriolis Flow Meters: These meters measure mass flow by detecting changes in vibration frequency of a flow-sensing tube. They are highly accurate and used in industries like pharmaceuticals, food processing, and chemical manufacturing.

Key Parameters:

- Flow Range: Varies by the type of flow meter. For instance, electromagnetic flow meters can handle flow rates from 0.1 m/s to 10 m/s, while turbine meters typically operate in the range of 0.3 to 10 m/s.

- Accuracy: Varies by the meter type. For example, electromagnetic flow meters offer accuracy of ±0.2% of reading, while ultrasonic meters can achieve ±1% of reading under optimal conditions.

2. Pressure Gauges

Pressure gauges are devices that measure and display the pressure of a fluid in a system. There are different types of pressure gauges, each designed to suit specific applications and environments:

- Mechanical Pressure Gauges: These include Bourdon tube and diaphragm gauges, which measure pressure through mechanical movement. They are often used in simple applications like HVAC, water treatment, and air compressors.

- Digital Pressure Gauges: These gauges use sensors to measure pressure and display the readings on a digital screen. They offer higher accuracy and can integrate with control systems for automated adjustments.

- Differential Pressure Gauges: These are used to measure the difference in pressure between two points, which is particularly useful for applications like filter monitoring, pump performance, and level measurement in tanks.

Key Parameters:

- Pressure Range: Pressure gauges come in a wide range of pressure ratings. For example, mechanical gauges typically measure from 0-100 psi up to 0-15,000 psi, while digital gauges can measure even higher pressures.

- Accuracy: Mechanical gauges typically offer accuracy within ±2% of full scale, while digital gauges can offer accuracy within ±0.1% to ±1% of full scale.

How to Use Display Instruments for Monitoring Flow and Pressure

1. Install Flow Meters and Pressure Gauges

The first step is to install your chosen display instruments in the correct location within the system. Flow meters are usually placed in a straight section of pipe to ensure that the flow is undisturbed, which is especially important for electromagnetic and turbine flow meters. Pressure gauges should be placed where they can accurately measure the pressure of the fluid without obstruction, often near pumps, valves, or at key junctions in the system.

2. Calibrate Instruments

After installation, flow meters and pressure gauges should be calibrated to ensure accurate readings. For flow meters, calibration is often performed using a known reference flow rate or volume, while for pressure gauges, calibration is typically done using a known pressure standard or test bench. Proper calibration ensures that the readings are reliable, which is crucial for system control and performance monitoring.

3. Monitor Data Continuously

Once installed and calibrated, the display instruments will begin providing real-time readings of flow and pressure. Continuous monitoring enables operators to identify any fluctuations or abnormalities in system behavior, such as sudden drops in flow or pressure surges, which could signal a problem in the system, like a clog or malfunctioning pump.

4. Automate Control

For systems equipped with automatic control systems like SCADA or PLCs, display instruments can be integrated into the system to trigger automatic adjustments. For example, if the flow rate exceeds a set threshold, the system can automatically adjust valves or pumps to maintain the correct flow rate.

5. Maintenance and Troubleshooting

Regular maintenance is essential to ensure the ongoing accuracy and functionality of flow meters and pressure gauges. Clean the sensors, inspect the equipment for wear or damage, and recalibrate the instruments as necessary. In case of system irregularities, display instruments provide the data needed to troubleshoot issues and make the appropriate adjustments.

Comparison of Peer Products: Flow Meters vs. Pressure Gauges

When selecting instruments for fluid system monitoring, it’s important to understand the differences between flow meters and pressure gauges, as they serve distinct functions but are both essential for overall system performance.

Flow Meters vs. Pressure Gauges

Flow Meters:

- Measure the rate at which fluid flows through the system.

- Can measure both volume and mass flow, depending on the type of flow meter.

- Often used in applications where maintaining a precise flow rate is critical, such as in chemical dosing, irrigation, and fluid transport.

Pressure Gauges:

- Measure the pressure exerted by the fluid within the system.

- Provide valuable data for monitoring the health of the system, preventing damage from overpressure or low pressure.

- Typically used in combination with flow meters for more comprehensive system monitoring.

Peer Product Comparison:

- Electromagnetic Flow Meters vs. Ultrasonic Flow Meters: Electromagnetic flow meters are ideal for conductive liquids and offer high accuracy (±0.2% of reading), while ultrasonic meters offer a non-invasive, cost-effective solution with a slightly lower accuracy (±1% of reading) but are suitable for a wider range of applications, including those with non-conductive fluids.

- Mechanical Pressure Gauges vs. Digital Pressure Gauges: Mechanical pressure gauges are simple, reliable, and cost-effective but offer less precision compared to digital gauges. Digital pressure gauges offer higher accuracy (±0.1% to ±1%) and are better suited for integration with automated systems for remote monitoring.

Industry Applications for Flow and Pressure Monitoring

1. Water Treatment Plants

Flow and pressure monitoring are essential in water treatment plants for controlling the inflow and outflow of water and ensuring that treatment processes are carried out under optimal pressure conditions. Flow meters monitor water distribution, while pressure gauges help manage filtration systems, pumps, and pipelines.

2. Chemical Manufacturing

In chemical manufacturing, flow meters and pressure gauges are used to control the flow of reactants, ensure the correct pressure for chemical reactions, and monitor the integrity of pipelines and reactors.

3. Oil and Gas

The oil and gas industry uses flow meters and pressure gauges for monitoring fluid flow through pipelines, pumps, and compressors, ensuring that pressure levels remain within safe limits and preventing leaks or bursts.

4. HVAC Systems

HVAC systems use flow meters and pressure gauges to monitor the flow of air and water in heating and cooling systems. This ensures that pressure is maintained to prevent system breakdowns and inefficiencies, improving energy use and reducing costs.

Conclusion

Accurate monitoring of flow and pressure is essential for maintaining the safety, efficiency, and reliability of fluid systems. By using display instruments such as flow meters and pressure gauges, industries can enhance system performance, reduce downtime, and ensure long-term sustainability.

At Hongguang Instrument Factory, we offer a wide range of high-quality flow meters and pressure gauges designed to meet the needs of diverse industries. Whether you’re managing water treatment systems, chemical manufacturing, or oil and gas pipelines, our products deliver the precision and reliability you need to optimize system performance and reduce risks.

By selecting the right instruments, performing regular maintenance, and integrating automated control systems, you can achieve efficient fluid management and avoid costly system failures.